company profile

Technology for the soul, service for this

development history

Our company replaces the gearbox for the world's largest OEM factory, marking the localization of the core parts of the imported extruder.

The birth of our company's first 480 differential mixing concentrator marks the beginning of localization of polymer post-processing equipment.

Reaction type intermeshing non-meshing large length-diameter ratio twin-screw extruder line marks the birth of domestic reaction type extruder.

To become a qualified supplier of imported gearboxes for GE Plastics in Asia.

Repair ZSK250 large gearbox and open the overhaul service of large import extrusion granulation device in petrochemical enterprises.

TM223 design and reconstruction of TM223 complete cylinder and threaded elements, upgrading and transformation of gearbox, and all-round upgrading of imported equipment.

Provide 12 sets of extrusion granulating devices for petrochemical industry (SPG process), and officially enter the extrusion granulating industry of polyolefin.

Entrusted by the owner and manufacturer, completed the installation and debugging of 400,000 tons PE and 260,000 tons PC devices in the petrochemical industry, and mastered the system integration technology of large imported extrusion granulation devices.

Completed the 2021 extrusion and grain preparation of Sinopec Jihua Branch overhaul service.

Responsible HPL330 swing extrusion equipment production

corporate culture

Advance always sticks to the enterprise philosophy of "technology first, craftsman set enterprise", and continues to carry out the development idea of "technology research and development as the core, craftsman spirit set enterprise". While optimizing the extrusion system, new application fields have been developed in the application of extrusion line. On the basis of consolidating the current market position, according to the market demand and the development trend of the new material industry, vigorously promote energy conservation, environmental protection and new energy, build a new development pattern, carefully carve every machine, with professional service to each customer.

technological superiority

Adopt the most advanced transmission structure in the world at present, that is, the output shaft force structure is the most reasonable "double side gear symmetrical drive form", and the first-line brands in Germany and Japan use the same transmission structure; The biggest advantage of this structure is to provide a long-term stability of high precision, high torque output guarantee, its life ≥72000 hours; Maximum specific torque up to 18Nm/cm3, maximum screw speed 1800rpm.

Our independently developed multiple functional components and mixed dispersed components provide greater processing flexibility for various materials and processing processes. Thanks to the stability of the gearbox system, our screw clearance value can be smaller (minimum to 0.1mm), and most domestic manufacturers to avoid screw interference with each other during the operation, the clearance value is more than 1.5 times of our's.

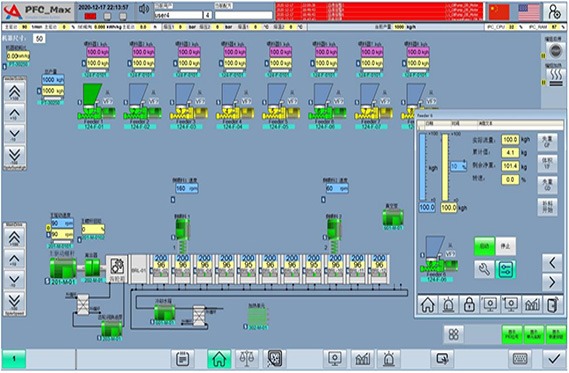

Intuitive human-computer interface realizes accurate temperature control, intelligent and humanized operation; online record, monitoring equipment and production operation conditions, monitoring energy efficiency, process and efficiency optimization design; complete cost control scheme, measure energy efficiency consumption; realize "energy saving" and "green" production for customers.

Provide customized design for different products and processes, tailored from torque, speed, cylinder arrangement, screw configuration, groove depth ratio, material, control system, to maximize accurate production and use efficiency.

qualification honor

Have questions about the product? We are always here to help you

Office phone028-85865728

faxfax028-85861108

company addressNO.4, Jinteng Road,Dujiangyan Economic Development Zone,Sichuan,China

18180485887 (Ms pu)

18030608060 (Mr Zhu)

18583903320 (Mr Xue)

sales@sc-advs.com

qiulin.zhu@sc-advs.com

xuesong@sc-advs.com